CNC Turning for Small Batch Production: The Flexibility Advantage

CNC turning is an innovative production process that has changed the landscape of precision machining and part manufacture. Companies concentrating on CNC turning have ended up being vital companions in diverse sectors, offering critical elements for vehicle, aerospace, electronic devices, and clinical sectors, among others. With the advancement of innovation, CNC turning devices have ended up being unbelievably progressed, enabling higher precision, quicker production prices, and the capacity to develop intricate geometries that were when laborious or impossible to accomplish with conventional machining methods. The essential operation of CNC turning entails the automatic process of turning a work surface while a reducing device removes material to create a preferred form. This procedure is controlled by a computer system program that dictates the movement of the reducing device, guaranteeing high levels of accuracy and repeatability.Among the crucial benefits of CNC turning is its ability to produce a broad variety of shapes and dimensions with snugly regulated resistances. This capacity is specifically critical in sectors where accuracy is vital. In the aerospace market, where every gram of weight matters, components have to satisfy stringent requirements to make certain security and performance. Aerospace designers usually rely upon CNC turning business to manufacture detailed components like turbine blades, real estate parts, and other machined fixtures that play a critical role in airplane functionality. Similarly, in the automotive sector, CNC turning is crucial for creating engine components, transmission components, and various other important assemblies that need both toughness and precise specifications.

Discover cnc turning company exactly how CNC turning transforms precision machining throughout sectors, boosting effectiveness, modification, and sustainability while meeting the expanding demand for premium components.

Along with accuracy, CNC turning additionally improves manufacturing effectiveness. Traditional machining commonly involves several setups, which can cause raised production time and higher expenses. With CNC turning, a solitary arrangement can create complicated elements, minimizing lead times considerably. Modern CNC turning facilities are equipped with several axes of turning, permitting synchronised machining of numerous functions on a component. A component can be turned on a turret while additionally being drilled, touched, or crushed, thus simplifying the entire manufacturing process. As a result, CNC turning firms can respond faster to customer needs, adapt to modifications in layout, and scale production quantities better.

In addition, the convenience of CNC turning enables it to suit a vast array of materials. From metals like light weight aluminum, brass, and stainless steel to compounds and plastics, CNC turning can be tailored to fit the residential or commercial properties of various materials. This flexibility makes CNC turning an invaluable resource for firms looking to discover innovative materials and applications. The surge of innovative materials, such as exotic alloys and titanium, necessitates precision machining techniques like CNC turning to make sure optimum efficiency in high-stress settings, such as those found in medical devices or aerospace applications.

An additional considerable aspect driving the growth of CNC turning business is the boosting demand for customization. As industries advance, the demand for one-of-a-kind, tailor-made elements comes to be extra obvious. CNC turning supplies the flexibility to generate small batches of specialized parts without the demand for pricey tooling adjustments, making it a suitable selection for business that require personalization. Whether it's a one-off model or a minimal manufacturing run, CNC turning offers a reliable option to fulfill special style specifications and transforming market demands.

Quality control is one more location where CNC turning excels. The assimilation of automation and computer system mathematical control permits regular tracking of the machining procedure, guaranteeing that parts are manufactured to the exact specs needed. Several CNC turning companies utilize rigorous top quality assurance methods, utilizing tools such as coordinate measuring makers (CMM) and laser scanners to confirm the accuracy of the ended up item. This commitment to quality not just boosts the credibility of CNC turning companies yet likewise builds trust fund with customers who depend on accurate components for their procedures.

As innovation proceeds to advance, CNC turning business are additionally rotating in the direction of Industry 4.0, which integrates smart innovations and the Internet of Things (IoT) right into manufacturing procedures. As an outcome, CNC turning companies are not only boosting their manufacturing abilities yet also driving development within their particular sectors.

The ability to recycle scrap materials created during CNC turning procedures is a growing pattern, allowing companies to contribute to a more circular economy. Improvements in maker modern technology have actually led to even more energy-efficient procedures, making it possible for CNC turning business to lessen their influence on the setting while keeping high manufacturing standards.

CNC turning firms frequently invest in training and advancement programs to ensure that their labor force is outfitted with the most current abilities and understanding needed to operate sophisticated equipment successfully. As innovation advances, constant learning becomes essential for staff members to maintain speed with advancements and maximize the capacities of CNC turning.

In exploring the future of CNC turning firms, one can not neglect the climbing pattern of additive production, or 3D printing, which, while a transformative innovation in its own right, does not change CNC turning but instead complements it. As firms look to invest in hybrid production methods that include both CNC turning and additive methods, the chances for technology are vast.

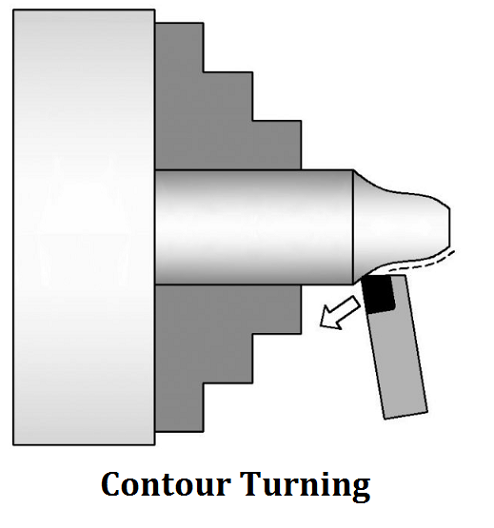

Discover contour turning just how CNC turning transforms accuracy machining throughout industries, enhancing efficiency, personalization, and sustainability while satisfying the expanding demand for premium elements.

The international landscape for CNC turning firms is likewise affected by elements such as globalization, outsourcing, and the drive for price decrease. Several businesses are aiming to CNC turning firms not just to provide top quality components yet likewise to use affordable rates that enables them to remain pertinent versus international rivals. Therefore, CNC turning companies are constantly trying to find means to improve procedures, lower overhead prices, and enhance supply chain administration. This dedication to efficiency assists CNC turning firms to thrive in a progressively open market, while also supplying worth to their clients.

With the increasing demand for high-precision elements in different markets, CNC turning firms play an essential duty in sustaining technology and ensuring that industries can achieve their goals. As they relocate onward, cooperation and collaborations in between CNC turning firms and their customers will certainly be critical in tackling new challenges and exploring the unlimited opportunities that accuracy machining has to supply.